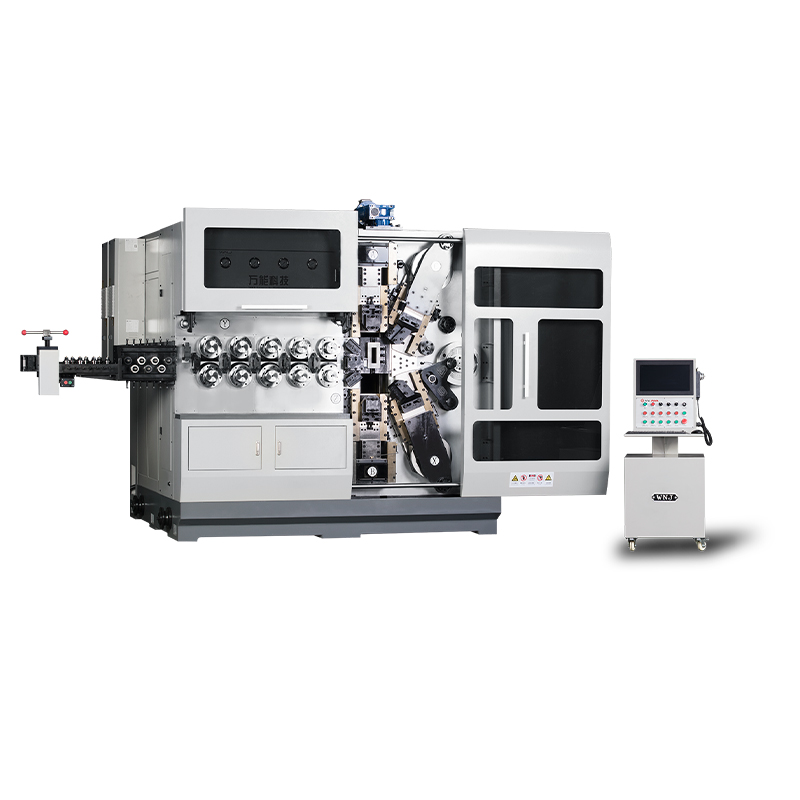

Die Dreiachsige CNC-Federformmaschine kann gewöhnliche gerade Federn, Pagodenfedern usw. herstellen, die im täglichen Leben und in der industriellen Produktion weit verbreitet sind. Neben herkömmlichen Federn kann die Maschine auch verschiedene Sonderformfedern wie Doppeltorsionsfedern, Rechteckfedern und Spiralfedern herstellen. Diese speziell geformten Federn verfügen häufig über besondere mechanische Eigenschaften und geometrische Formen, die den Anforderungen spezifischer Anwendungsszenarien gerecht werden können.

Die three-axis CNC spring forming machine supports the use of a variety of materials to make springs, including but not limited to carbon spring steel, alloy spring steel, stainless spring steel, copper alloy, nickel alloy, etc. These materials have different elastic limits, fatigue limits, impact toughness and heat treatment properties. Users can choose the right material according to specific application scenarios and performance requirements.

Die three-axis CNC spring forming machine allows users to flexibly adjust the outer diameter and angle of the spring according to specific needs. This flexibility enables the machine to produce springs with different geometric shapes to meet diverse application needs. In addition to the outer diameter and angle, users can also adjust other parameters such as the wire diameter, pitch, number of turns, etc. of the spring as needed. The adjustment of these parameters enables the three-axis CNC spring forming machine to produce springs with different mechanical properties and geometric characteristics.

Die three-axis CNC spring forming machine supports a variety of production processes, including cold coiling and hot coiling. The choice of these production processes depends on the material, size and performance requirements of the spring. For example, for spring wires with smaller diameters, cold coiling is generally used; while for spring wires with larger diameters, hot coiling may be required.

Die three-axis CNC spring forming machine has a high degree of customized production capabilities. Users can customize springs with specific shapes, sizes and performances according to specific application scenarios and needs. This customized production capability makes the three-axis CNC spring forming machine have a wide range of application prospects in industries such as aerospace, automobile manufacturing, machinery manufacturing, and electronic appliances.

TK-13200, TK-7230 TK-13200、 TK-7230 12-ACHSIGE CNC-FEDERWICKELMASCHINE ...

See Details

TK-13200, TK-7230 TK-13200、 TK-7230 12-ACHSIGE CNC-FEDERWICKELMASCHINE ...

See Details

TK12120 TK-12120 12 ACHSEN CNC-FEDERWICKELMASCHINE ...

See Details

TK-6160 TK-6160 CNC-FEDERWALZMASCHINE ...

See Details

TK-6120 TK-6120 CNC-FEDERWALZMASCHINE ...

See Details

TK-5200 TK-5200 5-ACHSEN-CNC-FEDERWICKELMASCHINE ...

See Details

TK-5160 TK-5160 5-ACHSEN-CNC-FEDERWICKELMASCHINE ...

See Details

TK-5120 TK-5120 5-ACHSEN-CNC-FEDERWICKELMASCHINE ...

See Details